End of smashed smartphones as scientists invent super-flexy touchscreen

Costly smartphone screen breakages could soon be a thing of the past after British scientists invented a cheap flexible touchscreen made of silver and graphene.

Current screens are so brittle because they are made of indium tin oxide and covered with glass, which can shatter easily when dropped.

Not only is indium tin oxide fragile, it is also difficult to extract from the ground, making touchscreens expensive to repair.

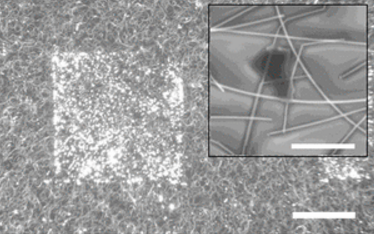

But now scientists at the University of Sussex have found it is possible to combine graphene - a material made from a single layer of carbon atoms - with silver nanowires, to create a film which matches the performance of regular screens, but at fraction of the cost.

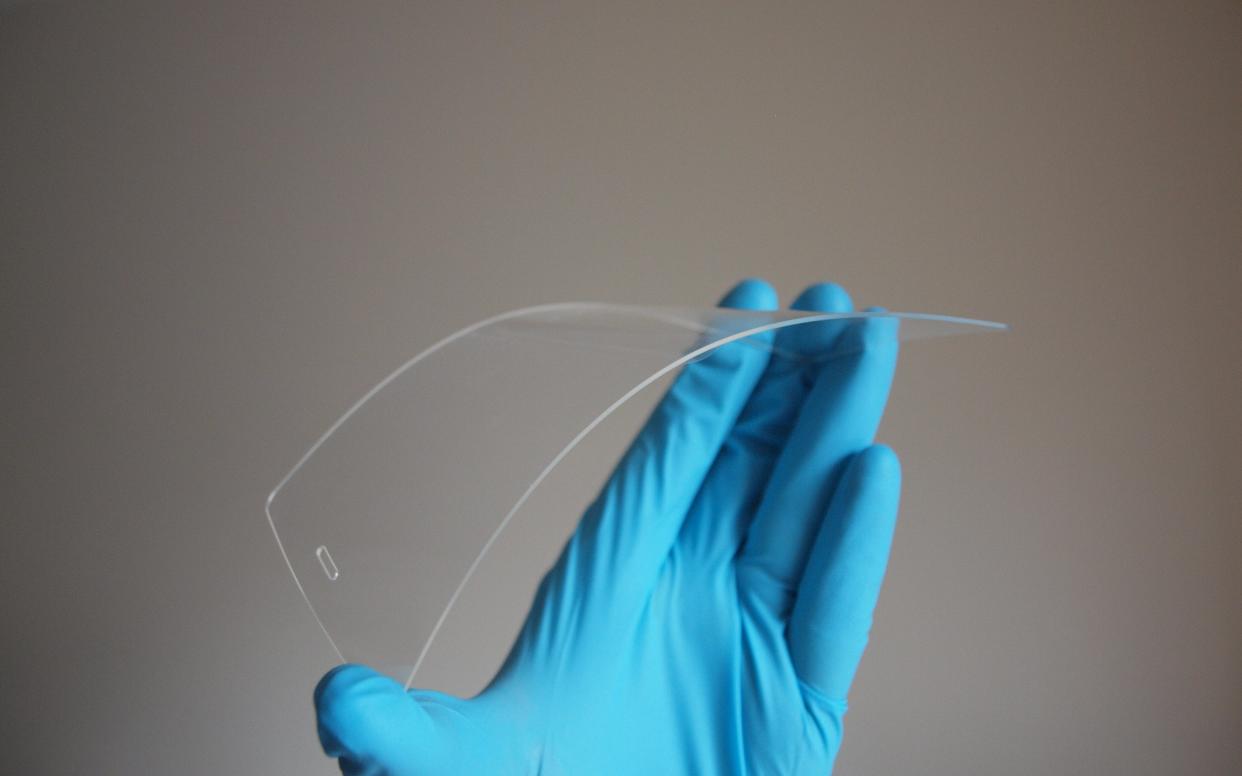

The material is also super flexible, so it would not need a protective glass coating, meaning the top layer of the screen could be made of something far more bendy and less breakable, such as acrylic.

Dr Matthew Large, lead researcher on the project at the School of Maths and Physical Science at the University of Sussex, said: “The reason that the screen on your phone is so easy to break is that the touch sensor is based on indium tin oxide (ITO). This material is very brittle, so needs to be deposited on a strong, hard surface like glass.

“It’s the glass layer that cracks if you drop your phone on a hard surface, or sit down on it by accident. Our latest development does away with the need for the hard glass surface because the silver nanowire-graphene hybrid films we produce are very flexible.

“We would still need a protective surface but it could be something far more flexible than glass. As a result your smart phone screen would be far, far less likely to crack when you drop it accidentally.”

Although silver is also a rare metal, unlike indium the amount needed to coat an area is very small when combined with graphene. Graphite, from which graphene is made is abundant so the cost could fall dramatically.

Scientists discovered it was possible to float the graphene particles on the surface of water, then pick them up with a rubber stamp, a bit like a potato stamp, and lay it on top of the silver nanowire film in whatever pattern they chose.

Professor Alan Dalton from the school of Maths and Physical Science at Sussex, said: “It would be relatively simple to combine silver nanowires and graphene in this way on a large scale using spraying machines and patterned rollers. This means that brittle mobile phone screens might soon be a thing of the past.

“The addition of graphene to the silver nanowire network also increases its ability to conduct electricity by around a factor of ten thousand.

“This means we can use a fraction of the amount of silver to get the same, or better, performance. As a result screens will be more responsive and use less power.”

Dr Large added: “This paves the way towards one day developing completely flexible devices.”

The new research was published in the American Chemical Society journal Langmuir.