How the Final Four Court Was Made

University of Phoenix Stadium is no freshman newbie when it comes to hosting a Big Game. It set the stage for the New York Giant's stunning victory against the New England Patriots in Super Bowl XLII and has hosted college football's national championship. Now this 63,000-seat stadium is getting ready for the NCAA Final Four, which requires a lot of creative engineering.

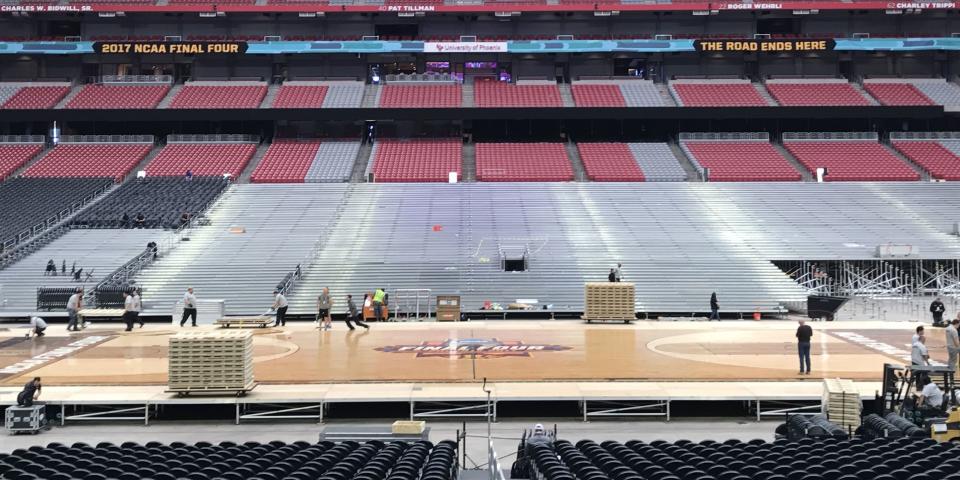

To get ready for the conclusion to March Madness, the University of Phoenix Stadium would need to transform, swapping in a basketball court, bringing in more seats right up to the action, and hoisting a giant video board onto a retractable stadium roof.

Getting a floor inside the stadium is a familiar dance practiced by multi-purpose stadiums around the world. The stadium's natural-grass turf (the home field of the NFL's Arizona Cardinals) rests on a retractable tray that slides out of the stadium completely to soak in the rays of the Arizona sun. Once removed, the team builds the court directly onto the concrete floor. Surface experts Connor Sports made this court special for the NCAA Final Four, harvesting wood in Michigan and milling it before having it stained, painted, and finished in Idaho.

But before crews could even put down the floor for the NCAA Final Four semifinals tip off, University of Phoenix Stadium needed to affix its crown jewel-a 700-ton board named Colossus.

This is the same scoreboard that adorned Bristol Motor Speedway in Tennessee for an NCAA football game in fall 2016 and has served two NHL outdoor games, too. Engineers had to figure out a way to safely hang the 700-ton scoreboard above the court. What would usually be a herculean task in any stadium was made even harder at the University of Phoenix.

"We had to engineer the method in which we were going to hang the board because our facility was not built with a center-hung scoreboard in mind," says Tom Sadler, president and CEO of the Arizona Sports and Tourism Authority, owners of the stadium.

The Colossus, featuring 764 LED screens in a ring, is only 14 feet shorter than the court below it. Along with video, it holds auxiliary lighting and sound needed to hover over the floor. Crews needed 100 tons of cables, tied into the stadium's scaffolding, to make sure Colossus would stay in place.

"It took about two years of designing and coordinating with our structural engineer," says Fred Corsi, executive director of operations at the stadium.

After taking five days to "pre-rig" Colossus in late February, crews spent another 10 days constructing and hanging the technological beast earlier this month.

Now with the video board in place, crews could install the custom-made floor-longer and wider than a traditional floor. At the same time, the stadium removed about 5,200 seats in the lower bowl to make way for a temporary riser system, constructed and cantilevered over the existing lower bowl seats and the sidelines. More than 16,000 temporary seats go on this riser system until it flows seamlessly into the permanent seating partway up the lower bowl, bringing the stadium's max occupancy to 75,000.

"Imagine all the sideline seats and start at the floor," Sadler says. "You can see row one and then how it gradually moves into permanent seating and blends in...It is a little bit of an art."

With the venue now wiped clean of its football persona, the thousands of fans descending on Glendale, Arizona, likely won't appreciate the amount of planning and sweat poured into the stadium's transformation, but they'll certainly enjoy the view.

You Might Also Like