Battery-mineral shortage likely to impede Canada's goals for electric vehicles, industry expert says

It's unlikely automakers will be able to meet their projections for electric vehicles (EV) as demand for the critical minerals that make up the batteries for them continues to rise, according to a noted business journalist.

Steve LeVine is editor of The Electric, a publication that focuses on electric vehicles and the lithium ion batteries that power them.

LeVine, who's based in Washington, said the world's mines only produce around half of the critical minerals necessary to meet the auto industry's EV goals.

This year, he said, automakers plan to build 7.7 million electric vehicles, but will only have access to enough nickel — a key ingredient in their batteries — to build around 3.6 million that can travel 400 kilometres or more on a single charge.

Even if they just focused on smaller short-range batteries, he said, there would only be enough raw material to build 6.3 million batteries.

"At the end of the decade, the desire is to make between 25 million and 40 million EVs, if you count the Chinese [industry] and Tesla," LeVine said.

"There's enough nickel to make 13 million."

Those supply constraints mean electric vehicles are likely to remain more expensive than gas-powered vehicles for some time, LeVine said.

The shortage of critical minerals — which includes nickel, lithium, cobalt and manganese — also means countries that have set ambitious deadlines to transition away from fossil fuels are unlikely to meet those targets.

Zero-emission vehicles by 2035

Last June, the federal government announced all new cars and light-duty trucks sold in Canada would be zero-emission vehicles by 2035.

"Let me just say, our target is ambitious, undoubtedly, but it is a must," Transport Minister Omar Alghabra told The Canadian Press at the time.

"We believe that it's doable. It needs determination, it needs focus, it needs effort."

But LeVine said his numbers would cast doubt on that goal.

"If you can't make enough batteries to make the EVs that get you there, then how do you have a year certain for zero emissions?" he asked.

LeVine said China has set itself apart from other countries, and has spent the last decade securing the critical minerals it will need to meet its own electric vehicle supply.

He said Tesla has also signed deals directly with mining companies to secure its own supply of metals. But traditional automakers like Ford, General Motors and Toyota have fallen behind.

Critical mineral strategies

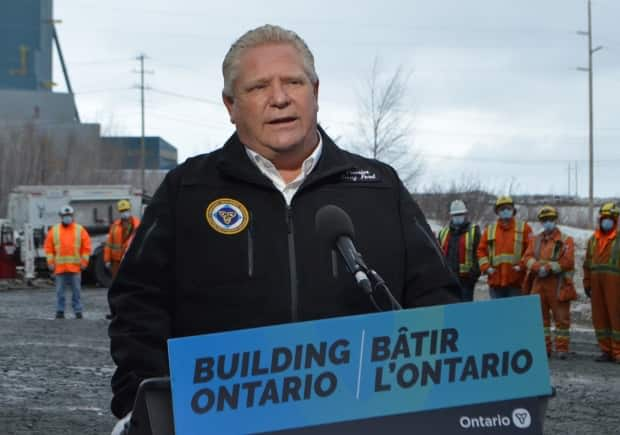

In March, Ontario Premier Doug Ford unveiled the province's first critical minerals strategy, which outlined plans to work closely with the mining industry to capitalize on demand for the minerals.

"This strategy details how we will strengthen our supply chains, how we will attract new investments to our province, and how we will ensure that the economic benefits are fairly shared with our Indigenous partners," Ford said during the announcement.

Trevor Walker, president and chief executive officer of junior miner Frontier Lithium, said the strategy would help make Ontario more self-reliant and make it easier for companies like his to bring their deposits to market.

In addition to Ontario's strategy, the last federal budget set aside $3.8 billion over eight years to develop a national strategy for critical minerals.

As with Ontario's plan, the goal is to increase Canadian production of the critical minerals that would boost the economy and help fight climate change.

LeVine said domestic supply of battery materials, across North America, is likely to catch up with demand by the late 2030s.