New Brunswick getting 'ship shapes' with new 3D printing lab

3D printing is setting sail in New Brunswick to revolutionize another field of traditional manufacturing.

The University of New Brunswick announced the launch of the Marine Additive Manufacturing Centre of Excellence Thursday morning. The new lab will create and manufacture components for marine vessels, including industry, research and defense craft.

"This is going to change the game," said Mohsen Mohammadi, the new director of the centre, and assistant professor of mechanical engineering at UNB. "This printing process is the future."

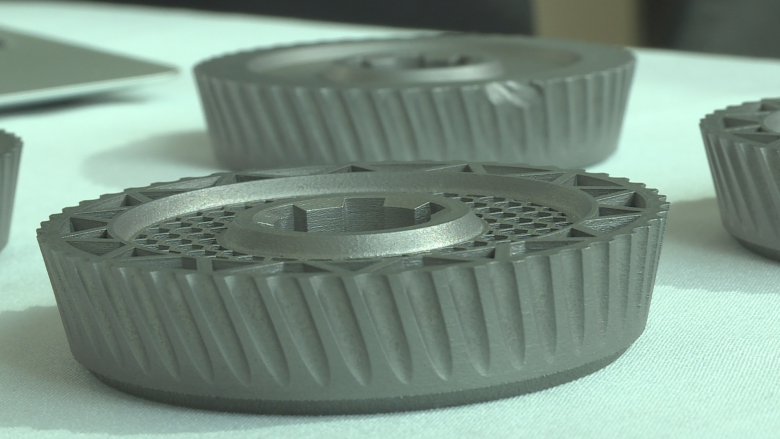

Mohammadi said once his metal 3D printers are delivered and operating they will construct components roughly 60 by 60 by 60 centimetres, such as heat exchangers, intricate parts of the cabin and controllers. But he expects larger structures to be built as the technology improves.

"Right now the regular manufacturing and the regular practices are very time consuming," said Mohammadi. "With those we need casting, which can sometimes take up to 60 weeks in lead time to get a part. With this we can create this part in only eight hours."

Mohammadi said the lab is working with stainless steel but also developing some new alloys for the marine sector using nickel, aluminum, titanium and original steel.

"It's all because of strength, with corrosion, with fatigue properties and also impact resistance," said Mohammadi, who described his elevation to the position overseeing the new lab as the best day in his academic career.

Large investments

Funding for the creation of the printing lab comes from a number of large corporations with interests in ship construction. Lockheed Martin Canada announced it is contributing $2.7 million and Irving Shipbuilding Inc,. also announced a contribution of $750,000.

"The total investment in the Marine Centre is nearly $5 million," said UNB chancellor Allison McCain. "But it gets better, because we expect that before the end of the year we will have another $10 million in that centre."