Yellowknife's Stitch'in Gwich'in finds success in sewing machine repair business

Roger Fraser knew he'd be busy when he opened his sewing machine repair business in Yellowknife last January; afterall, Stitch'in Gwich'in Sewing Machine Repair and Sales was — and remains — the only business of its kind in town.

But the retired government worker did not expect it to be this busy.

Fraser estimates he's tightened and tweaked several hundred machines since opening shop, for an average of four to five sewing machines a day, depending on the time of year.

"I like to slow down in the summer," Fraser says with a chuckle. "I'm retired you know."

Many of the repairs are long overdue. Fraser estimates some machines haven't been serviced in 10 to 15 years — or ever — because typically, it cost more for freight than for repair.

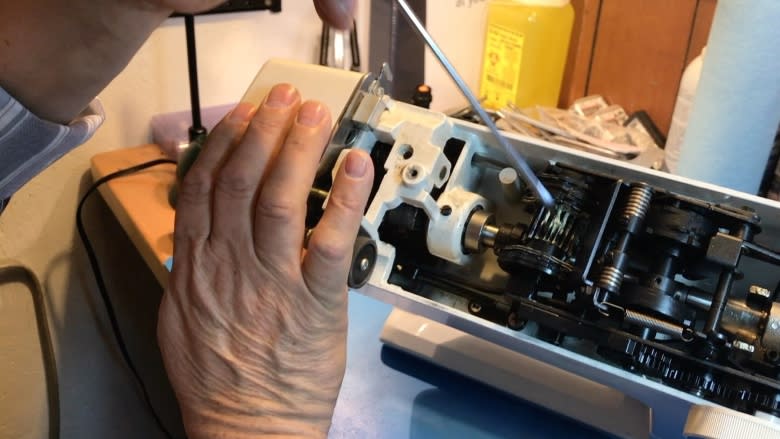

"You open them up and you see the grease in them and the oil has turned to a white and yellow putty so that slows your machine down and makes it sluggish. Once you clean them up and re-time them, they work properly," Fraser says.

His wife Karen Wright-Fraser, an accomplished seamstress, encouraged Fraser to go into business.

"She was the same as everybody else. A machine would break down and she just bought another one. So she said, 'why don't you repair sewing machines?'"

A friend, who knew Fraser is from the Gwitch'in First Nation, suggested the name.

Slow but steady growth

Fraser's clients include sewing groups, schools and individuals like Sandra Pryftupa.

"I was delighted with the work that Roger did," Pryftupa said.

She says two of her older machines that Fraser repaired are working "like new."

Pryftupa welcomes the opportunity to shop locally.

"It's wonderful to do business with people who live and work in the North. And not rely on services in the South," she said.

Yellowknife quilter Marilyn McGurran says the service Fraser provides is "priceless."

"We know the value of having someone like him here," McGurran says.

Sewing groups in South Slave and Tlicho communities are having Fraser visit to do some repairs.

Fraser recently added scissors sharpening, a welcome service for people working with moose hide and leather.

Challenges and future projects

But Fraser's business journey wasn't easy, and it still comes with challenges.

In order to get parts to fix his machines, he's bound by his high-end suppliers — like Brother, Singer and Bernina — to sell their products.

That's difficult, he says, because he's up against big-box stores like Walmart and Costco who sell machines at half the price.

"They are made of plastic and only last a year or two ... The ones that I'm selling have metal frames, they are solid. So if you hit a seam on a pair of jeans it's not going to knock things out of whack," he says.

Fraser has also bought a commercial sewing machine. The plan is for the couple to start repairing canvas tents, tarps and teepees. But that's in three years, when his wife joins him in his so-called retirement.

"I've been working since I was 15. This is work I enjoy and I can do on my own time. I might be down in the shop at 9:30 or 10 at night working on a machine, or early in the morning or take the day off. There is no stress and deadlines," he says.

"A lot of people are happy I'm here … I am too," he says