This Yellowknife couple is using 3D printing to make masks more comfortable

Photos of health-care workers' sore and swollen faces are going viral on social media, as many are forced to don uncomfortable protective equipment to prevent the spread of COVID-19.

That prompted one Yellowknife doctor and her 3D printing enthusiast husband to come up with a solution.

"In the emergency departments … we're now using face masks a lot more frequently — basically with every patient that we see," explained Dr. Kate Breen. "So a mask that would typically be worn for a single patient encounter we wear for potentially hours at a time."

Those masks are equipped with elastic loops that go behind the ears and keep the mask tight — vital, but very uncomfortable, Breen said.

"After a couple hours, I found that my ears were getting really achy," she said. "And the nurses were agreeing — 'we're getting chaffed back there.'"

For a while, Breen and her colleagues struggled along with finicky solutions involving paper clips and hair ties. But those made it harder to remove the masks, and increased the risk of contamination.

So Breen and her husband, Eric McNair-Landry, put their considerable minds to work finding a way to keep the masks effective while making them a little more comfortable.

Fortunately, it was a problem that health-care workers around the world were more than familiar with.

McNair-Landry found a variety of straps and buckles online designed to alleviate the pressure of medical masks. After trying a few different models, they settled on one they liked from the online library Thingiverse.

"It's basically a very thin plastic strap that fits kind of behind the head," he explained. "The [part of the] mask that normally loops around the ears … loops around these little holders in this plastic frame."

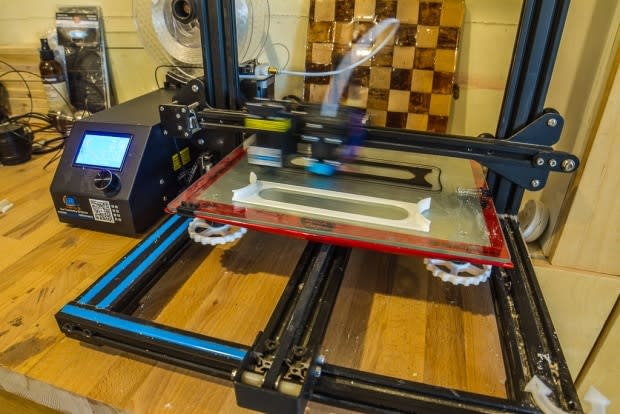

McNair-Landry took to his workshop to fire up his 3D printer, and started an assembly line.

"It's kind of the joy of 3D printing," he said. "Once you've designed it, it's pretty quick to replicate."

"It works great actually," said Breen. "They are super popular in emergency where I work."

McNair-Landry said he's made about 30 so far, and hopes to make 50 or 60 before he switches projects.

"We'll try to meet the need," he said.

Once he's done that, he said, the couple will focus on printing face shields, following in the footsteps of fellow 3D printers elsewhere in the North.