This made-in-LaSalle, Ont., machine is being built to go to Mars

Tucked away in an inconspicuous-looking building on the outskirts of LaSalle, Ont., a team is building a machine that might one day go to Mars.

This project, known as ISXRD, is a highly portable, compact x-ray diffractometer: A machine that can tell scientists the composition of a material through a series of x-rays. It's a collaboration between LaSalle's Proto Manufacturing and Western University, and the project has received funding from the Canadian Space Agency.

With years of work ahead, it might some day change how scientists think about and analyze soil samples collected in space.

"The end goal would be extraterrestrial, with the focus being on Mars," said Stanislav Veinberg, one of the project's application scientists and project development manager.

"You can actually map, almost, the history of a planet based on the rocks or the formations that you can find .... so if you take a rock and you do find some remnants of water in there that could hint to, there's water on Mars."

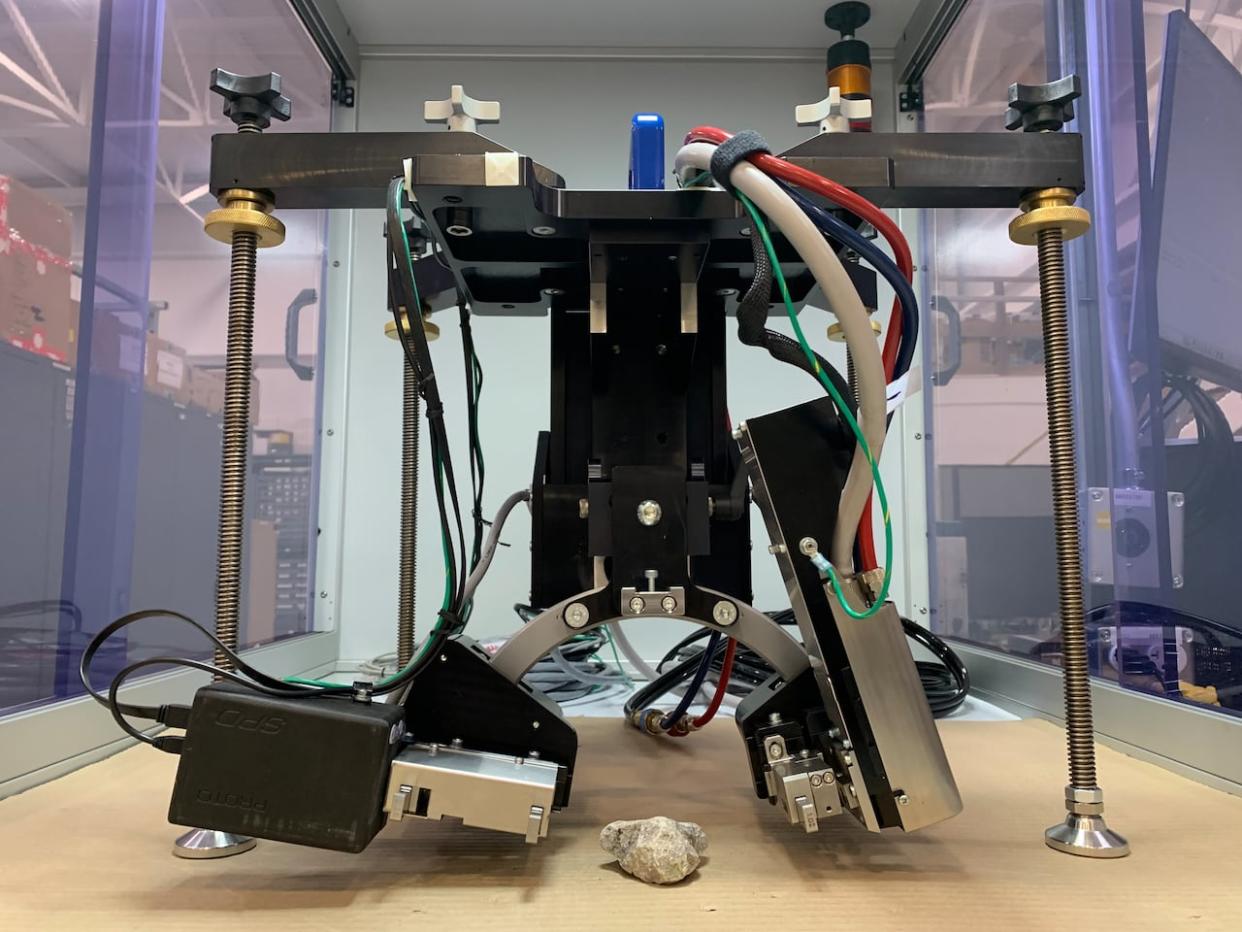

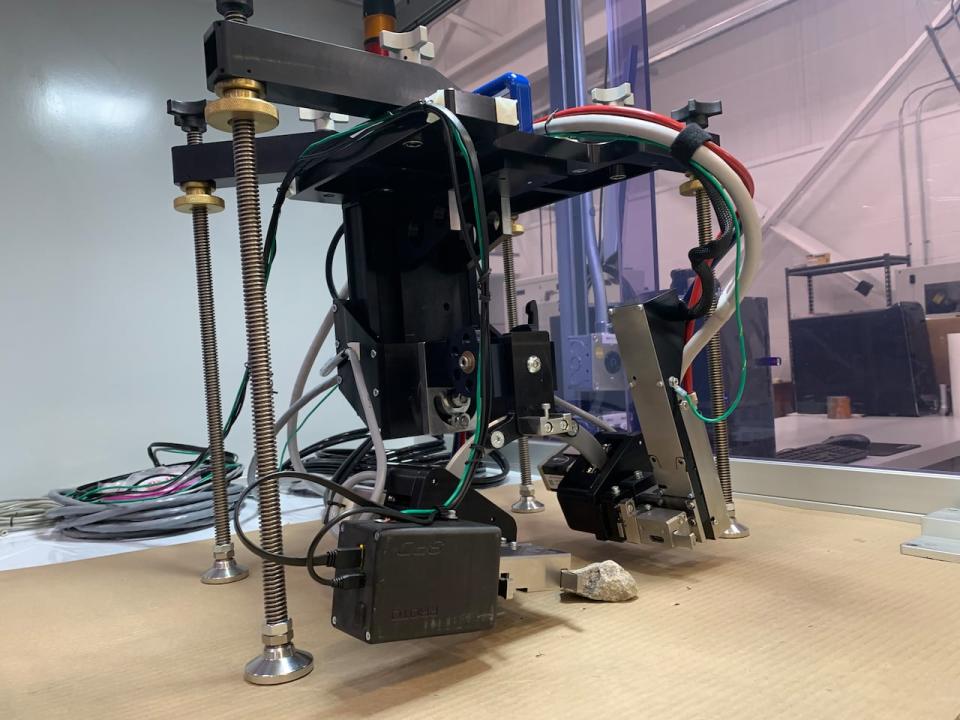

A group of researchers from Western University and Proto Manufacturing in LaSalle are building and developing an x-ray diffractometer, a tool that can be used to x-ray samples almost anywhere — including, one day, in space. (Western University)

It took a trip to Texas to connect the team at Proto Manufacturing and Roberta Flemming, an earth sciences professor at based just down Highway 401 at Western University in London. Flemming had first envisioned the concept as far back as 2008.

"I had approached the big x-ray diffraction companies ... and none of them were interested then," Flemming said. "But we go to this lunar and planetary science conference ... every year in Texas, and Proto had a booth — this Windsor company, from Canada, and we met them in Texas."

The main difference between this machine, and other machines like it — including one that's currently in space — is that it can x-ray specimens in place and doesn't need to drill them into a powder before they can be analyzed, meaning it can provide results without having to alter the sample.

"If you have weird samples that can't necessarily be inserted into a machine, you can use this without necessarily having to destroy the specimen," said Izabela Kolodziej, an application scientist on the project.

While sending the machine to Mars is, to put it lightly, a while away, the machine has other applications: research work like geology and archeology. It could be used by the military, to determine whether an explosive had gone off in a particular location or whether soil is contaminated with radiation.

Currently, other types of this machine are used in the pharmaceutical industry. Some natural history museums even use x-ray diffractometery to determine the composition of artifacts.

But on Mars, it could open a new frontier of research, telling scientists a "history" of sorts of the planet's surface: when and where a meteor hit the planet, and even whether there was water present.

Building the model started in 2022. And last fall, the team had a successful field test, using minerals to test the ISXRD in Proto's parking lot. It could deliver reliable results in as little as 17 minutes.

"I think it was fantastic," Flemming said of the test, noting she feels optimistic about future funding. "It was the whole team. It went so well and so we're all excited.

"It was a fantastic conclusion to our three years of research and we're all excited to get the next funding and built generation two."

This x-ray diffractometer could one day be used to analyze soil samples and material on Mars. It is being developed by a team at Proto Manufacturing in LaSalle with a team from Western University in London. (Kathleen Saylors/CBC)

From here, the team is submitting their reported results and awaiting news on the next round of funding. If they're successful, it'll be a five-year project to make the machine more autonomous and durable enough to withstand the cold temperatures and low pressure of space.

"Making sure that as soon as we send into space, it doesn't just fall apart," Kolodziej said.

Both Veinberg or Kolodziej say they never thought their careers would take them to making tech that could one day be in space.

"I think that's actually one of the exciting parts is that it's not something I would have envisioned facility in Windsor doing. When I think of space projects, I think Toronto or Montreal," Kolodziej said.

"Windsor is known for its automotive industry, but there's a lot of promising science careers and I think it's awesome that this is one of them ... I never thought my career would take me here."