Dow to invest $8.9 billion in Alberta's Industrial Heartland for net-zero petrochemical project

Alberta Premier Danielle Smith and Deputy Prime Minister Chrystia Freeland announced Wednesday that an $8.9 billion investment by Dow will move ahead in Alberta's Industrial Heartland.

Dow's Path2Zero facility, to be built in Fort Saskatchewan, will be an integrated ethylene cracker and derivatives site that is net-zero with respect to scope 1 (direct) and scope 2 (indirect, from the use of purchased energy) carbon dioxide emissions. Dow says it is the world's first net-zero complex.

Fort Saskatchewan is one of five municipalities that make up the designated industrial zone located northeast of Edmonton.

The project will produce and supply approximately three million tonnes of low- to zero-carbon emissions polyethylene and ethylene derivatives for customers around the globe, according to Dow.

"At nearly $9 billion, this project is one of the largest private sector investments in Alberta's history," Smith said.

The Alberta Petrochemicals Incentive Program (APIP) will contribute approximately $1.8 billion dollars to the project. The federal government will be contributing up to $400 million from Canada's carbon capture, utilization and storage investment tax credit as well as the clean hydrogen investment tax credit.

"That is money that's going to be delivered upfront to get shovels in the ground," Freeland said.

Construction will begin next year, with phase one expected to be completed by 2027 and phase two in 2029.

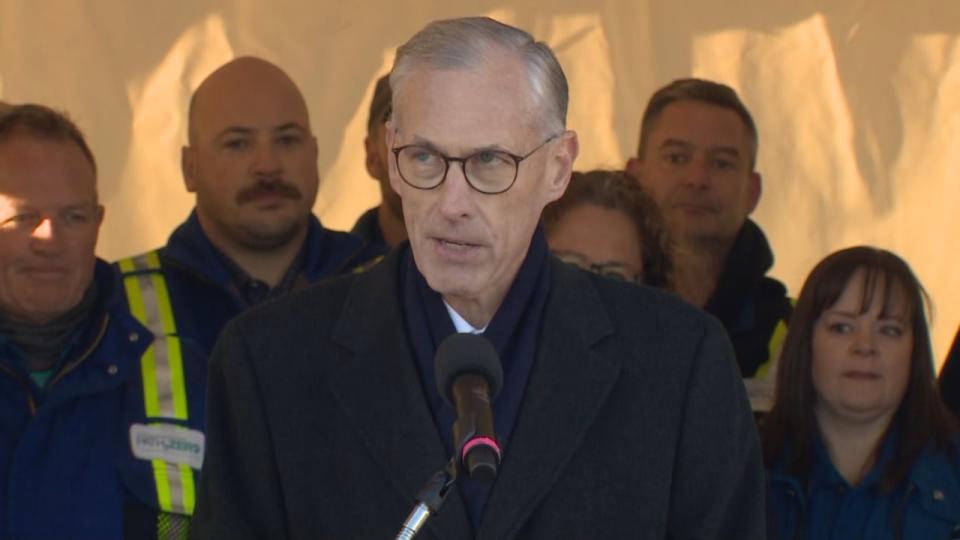

Jim Fitterling, Dow's chief executive officer, said Wednesday the project will decarbonize 20 per cent of Dow’s global ethylene capacity. (Trevor Wilson/CBC)

Jim Fitterling, chair and CEO of Dow, said the facility increase polyethylene capacity by two million tonnes per year while decarbonizing 20 per cent of Dow's global ethylene capacity.

"It will serve as a leading example that industrial decarbonization is not only possible but can also be profitable," Fitterling said.

The U.S.-based company said it chose Alberta for the project because it offers cost-competitive natural gas as well as cost advantage ethane, a key feedstock for ethylene production.

"The region also features access to existing CO2 transportation and storage infrastructure with the available capacity to fully support the decarbonization of this project," Fittering said.

Dow makes plastic polyethylene pellets. Manufacturers use those pellets to make products like face cream bottles, yogurt tubs and the plastic used to wrap cheese or lunch meat.

Investments by third parties that will provide services and support to the project will bring another $2.7 billion as it comes to fruition, says Dow.