University clean room to aid in nano-technology research

Imagine a device that can help a firefighter make his way through a smoke-filled building, or a sensor that a heart patient could wear to detect early signs of cardiovascular disease. That's the type of cutting edge technology being developed in the engineering labs at the University of Windsor.

But even though they can design the microchips, and later test them after they have been manufactured, they don't have a facility to make them yet.

That's about to change. The university is about to install a new clean room called a microfabrication facility in which sophisticated filtration equipment controls such things as dust, temperature and humidity.

Those controls are necessary in order to produce flawless microchips which are so small that even particles of dust can render them useless.

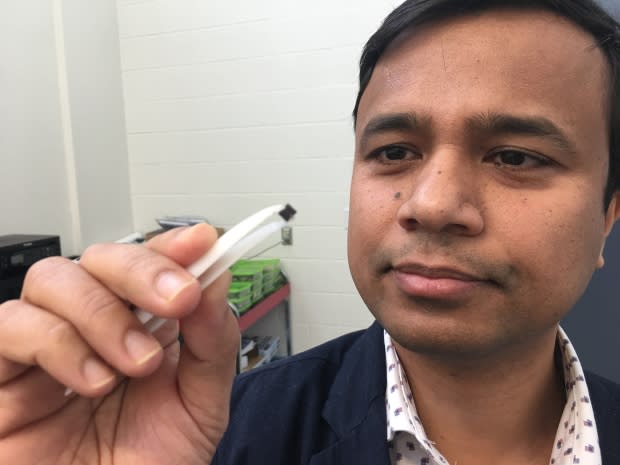

"So to make those chips in that small size you need a special environment where you control how much particle you allow in that room because some of the features are smaller than the size of a particle," said Jalal Ahamed, assistant professor of mechanical engineering.

Ahamed is working on micro and nano technology which can be used in a variety of different sensing equipment. Right now they have to have the microchips fabricated in other universities or government facilities, which takes a lot of time.

"This facility that we are putting together at the University of Windsor will enable them to do everything in house," said Mehrdad Saif, Dean of Engineering.

Saif estimates the cost of the new clean room will be around $1.5 million. The room is empty right now but once equipment is installed and some renovations are completed it should be ready sometime next year.