Take an exclusive peek inside Campbell’s Snacks Charlotte plant, home of Lance crackers

The sweet doughy scent of Lance sandwich crackers being baked has wafted through the south Charlotte air for 61 years.

But the iconic snack company, in business in Charlotte for over a century, has been evolving and remains embedded in the community, with more change ahead. Lance has survived mergers and an acquisition, and is one of the oldest operating companies in the city.

“It’s always been an integral part of Charlotte,” said Quincy White, great-great-granddaughter of Lance founder Philip Lance. “Lance was family.”

Lance is now owned by Camden, N.J.-based Campbell’s Soup Co.

During a recent, exclusive tour of Campbell’s Snacks plants in south Charlotte, including Lance, tarps covered parts of the office wing where construction is underway renovating space to house more than 100 workers.

It will be a two-story office with more open space floor plan as the company consolidates and closes its longtime Ballantyne offices, Campbell’s spokeswoman Michelle Reardon said. The offices are expected to open in the spring.

Known for its bright orange cracker peanut butter sandwich, Lance remains the “largest snack plant in the network” for Campbell’s, said Josh Logan, associate vice president of operations in Charlotte.

Campbell’s Snacks in Charlotte has over 1,500 employees with three plants, a mixing center, a distribution center and a warehouse totaling over 1.2 million square feet.

The Campbell’s Snacks site in Charlotte produces 215 million pounds of Lance sandwich crackers , cookies and chips each year, according to the company. The Lance brand itself is sold in 48 states.

Inside the snack plants

Visible for miles, the name Lance is emblazoned on the water tower at 8600 Crump Road.

Inside the plant before entering the green door marked with a sign “Campbell’s Snacks Bakery Production Plant Entrance,” Logan, who oversees the plant operations, shared where some of Lance cracker ingredients come from.

The peanuts come from Georgia. And about 80% of the flour comes from within 10 miles of the plant, he said.

Over the years, methods for speeding up proofing of the dough have changed from a cold, two-step process to a hot process, using high humidity to activate the yeast. “Before it would have to sit in that room for almost 24 hours,” Logan said of the dough. “Now, it only has to sit there for like four to five hours.”

Once inside the 700,000-square-foot Lance cracker bakery, there’s a sanitizing station for workers and plant visitors. The Lance plant has seven cracker lines including five sandwich semi-automated conveyor lines, each a quarter-mile long.

On the first line is the well-known crispy orange crackers coming out of the dough room. About 2,000 pounds of dough is mixed daily, Logan said.

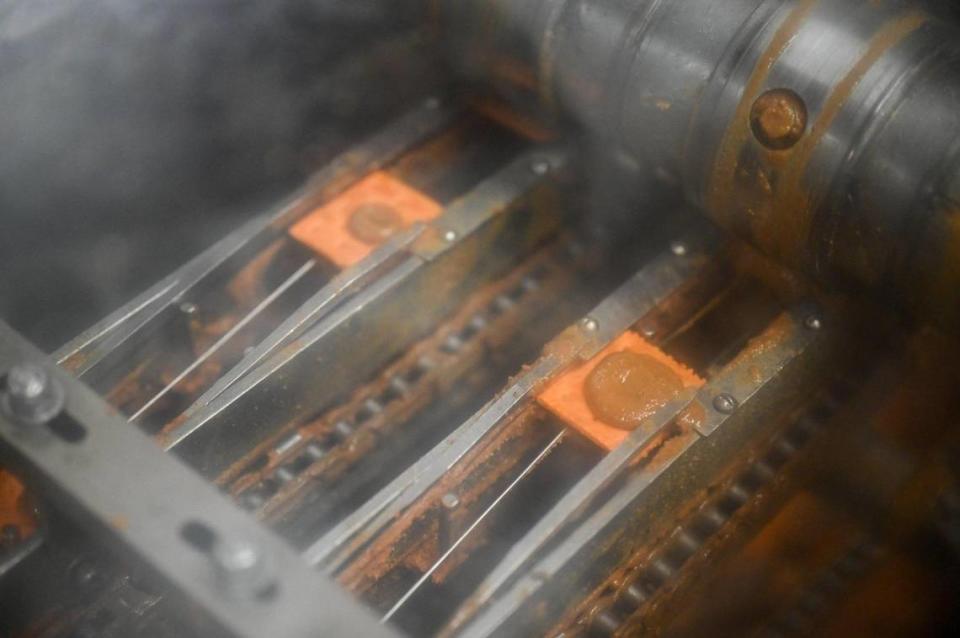

The hot, orange dough moves along a conveyor line from the second floor, flattening the dough into a specific thickness. Then the dough is folded as thick as a hand, filling the width of a conveyor belt and being compressed to its final thickness to be baked into crackers.

A rolling cutter then slices it into snack-size portions. Pins on the cutter puncture the dough, giving it a dimpled look and allowing steam to escape during cooking and making the crackers crispy, Logan said.

Then it moves swiftly along into the ovens with different heating zones. The hottest is 700 degrees.

Then the crackers are cut along lines and sprayed with vegetable oil, moving along into stacks. Workers toss damaged and overcooked crackers. The cheese crackers then are lined up and descend to be filled with a dollop of peanut butter, before eventually heading to packaging and wrapped in plastic wrap.

Along the way, worker stations are set up with employees donning hairnets, gloves and earplugs, checking the crackers’ weight, how it is cooked and for other consistencies. Inspections also are done by laser and robot.

“It’s a lot more scientific than people may realize,” Logan said.

Toast Chee packages run beneath a laser scanning device, then into a robotic packaging system and placed in cartons. Again, workers inspect packages as they move down the line that twists and turns. The Toast Chee crackers are then packaged and sealed for distribution

About 1,400 Toast Chee packages are produced every minute at the plant.

The sandwich lines make 16,000 crackers every minute, Logan said. The snack fillings also are made in-house. Lance has 17 varieties of sandwich crackers, including popular Toast Chee, Toasty, Nekot and Captain’s Wafers, Whole Grain Sandwich Crackers, Saltine Crackers and Popcorn.

The ‘salty’ Lance plant

We exited the Lance plant through a tunnel to get to Campbell’s 250,000-square-foot so-called “salty” plant, where chips and popcorn are made.

After another sanitizing station, this plant is much cooler, and wetter, with an earthy scent as potatoes move along a conveyor belt getting watched washed and peeled.

This plant has 10 chip kettles. Brands include Cape Cod, OkeDoke Popcorn and Tom’s Snacks.

What’s now and next

This year, change at Campbell’s Snacks in Charlotte has included about 175 jobs cuts. Campell’s closed one of its three snack plants at 8600 Crump Road, Emerald Nuts, next to the Lance plant. Campbell’s also eliminated about 50 corporate jobs as it consolidates its Charlotte office and moves to the plant site from 13515 Ballantyne Corporate Place.

Plans are already in the works for the former nut plant, however, Campbell’s officials declined to say what might be in store or how soon it could be operational.

Still, Logan says the Campbell’s Snacks division focuses on workforce development. There’s a partnership with York Technical College in Rock Hill and an onsite training lab. “There’s a heavy emphasis to build the next generation,” he said.

Jacob Martin, 26, of Fort Mill, South Carolina, is a process manager in Charlotte. He graduated with a bachelor’s degree in chemical engineering from Clemson University, a degree that helps with “principles of problem-solving,” he said.

But growing up eating the Lance crackers, what he likes most is the work environment. “We’re all one big team,” he said.

The plant has a good mix of longtime and new employees, Logan said.

That includes people like Janice Blakeney, 68, who started with Lance 47 years ago as a packer on the salty line. Now she’s on the company training team.

“I was a country girl coming here, but by God when I get ready to leave, I’m gonna leave with a lot. Not financially, but all the things that I enjoyed doing,” she said. “That’s why you need to do something you love because it’s almost like you’re not working.”

How Lance crackers started

It all started from a mistake.

In 1912, Philip L. Lance was a food broker and coffee bean broker, said White during a visit at Lance’s former plant on South Boulevard, 7 miles north of the current site.

White is not only the family historian but chairwoman of the Philip L. Van Every Foundation, which has an office at the former plant building. Her grandfather was the last family member to run the Lance company.

Van Every served two terms as mayor of Charlotte and a bronze statue of him stands at Trail of History near uptown Charlotte. He’s holding a four-pack of crackers in his hand, White said.

But back to the beginning. Founder Lance got stuck with 500 pounds of raw peanuts, White said. A customer may have ordered the nuts or he got the nuts instead of coffee beans. “We’ll never know,” she said.

Lance’s wife, Nancy, hatched a plan to roast the peanuts using the family kitchen. Lance sold the nuts on the streets of uptown for 5 cents a bag. “The peanuts were a big hit,” White said, “and so they started making peanut butter.”

Lance also was a candy company, but when World War II brought sugar shortages, it pivoted. Lance’s wife and daughter, Mary Lance Van Every, are credited with creating the sandwich concept suggesting serving the peanut butter on crackers for samples, which led to the Lance crackers sold today.

Lance through the years

1912: Lance Packing Co. was founded in 1912 by Philip L. Lance. in Charlotte.

1922: Lance and his business partner and son-in-law, Salem A. Van Every, moved the plant to West Ninth Street, north of uptown.

1926: Lance moved to 1300 South Blvd. and expanded the the plant four times. The same year Lance dies and Van Every takes over.

1943: Van Every dies and son Philip L. Van Every takes over Lance.

1962: Lance moves to its current site at 8600 Crump Road on 108 acres off South Boulevard.

1972: The salty plant opens.

1973: When Philip L. Van Every retired in 1973, the company was making $80 million in sales.

2010: Lance and Snyder’s of Hanover merge.

2018: Campbell’s Soup purchases Snyder’s-Lance for nearly $4.9 billion.